Novosibirsk Institute of Organic Chemistry Siberian Branch of the Russian Academy of Sciences has developed high-performance non-toxic and nonstaining additives-modifiers of polymeric materials – СО-3, Stafen, Benzon-P, TAB, CО-4, Kalixaren – used inlight- and termostabilization of polypropylene, polyethylenes of high and low pressure, polystyrenes ABC- plastics, radiation- or peroxide cross-linked polyethylenes, epoxide, and rubbers. Unlike many applicable polymeric additives, the novel stabilizers developed in Novosibirsk Institute of Organic Chemistry possess unique combination of useful properties which makes them a new generation additives to polymers:

- Non-toxic (belong to III-IV class GOSTof 12.1007.76)

- Do not dye polymeric materials

- Polyfunctional

- Practically non-volatile, thermostable at temperatures higher 250оС

- In mixtures with amino- and sulfur-containing stabilizers show a synergy effect – substantial strengthening of stabilizing efficiency

- Improves stability, bending resistance, durability, steadiness to mechanical loading of the goods from polymeric materials

The developed stabilizers are synthesized from available domestic materials in standard technological equipment.

The stabilizers CO-3, Stafen, Benzon-P are authorized by the Public Health Ministry and can be used in the goods contacting with foodstuffs and human body.

Novosibirsk Institute of Organic Chemistry pilot plant produces development batches of additives to polymers.

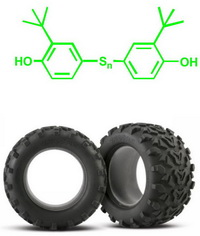

STABILIZER TAB

Stabilizer TAB is an effective modifier of performance properties of technical polymers. Besides, it has a high antioxidant efficiency. It is moderately toxic and low volatile. It is very soluble in usual solvents. TAB modified polymeric goods have natural coloring which is preserved in operation.

In composition with amine stabilizers, TAB significantly strengthens its properties.

TAB is a slightly colored adherent resin or its solution in toluene. The content of di- and polysulfides in the resin is not less than 50%.

Advantages

- Universality: TAB – modifying additive for a wide range of polymers with processing temperature being higher 140оС (rubbers, epoxide, polystyrenes, ABC-plastics, polyolefines, polyamides).

- Increase of operation life of polymeric goods containing TAB and the possibility to use them in extreme conditions: under the conditions of overheating to more than 230оС, intensified load impacts and bending deformation the goods preserve their operation properties during several hours unlike industrial additives-stabilizers which tend to decay within several minutes under the similar conditions.

- Providing essential requirements to the goods: weather- and radiation resistance.

- TAB is one of the cheapest additives nonstaining polymer materials. It is produced on the basis of cheap available domestic raw materials on the standard equipment.

Practical realization

Technological methodology of TAB production has been developed. Novosibirsk Institute of Organic Chemistry pilot plant produces and certifies development batches of the product. Full-scale industrial testing has been successfully completed in the production of tire rubbers, fiberglass plastics, epoxide and peroxide cross-linked compositions.

Application

Thermostabilizer and modifier of polymeric compositions, ABC-plastics, polymers produced on the basis of epoxide, eroxide cross-linked and radiation cross-linked compositions based on polyethylene and polyvinylacetate is used in the production of all-weather microelectronics, benzine-resistant and tire rubbers. TAB is effective in the production of fiberglass plastics and other filled compositions used in the production of domestic goods exposed to short-term extreme loads.

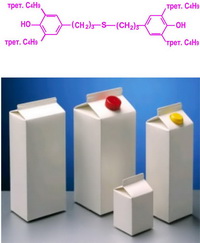

STABILIZER СО-3

Description

Stabilizer СО-3 is a polyfunctional additive:

- high-performance antioxidant of organic materials (foodstuff, medication, monomers);

- nonstaining high-performance thermostabilizer;

- modifier of the main service properties of polystyrenes, ABC-plastics, radiation- or peroxide cross-linked polyethylenes, epoxide, significantly reinforcing their firmness and stability.

Stabilizer СО-3 is a non-toxic substance. It is authorized and certified by the Public Health Ministry of the Russian Federation and can be used in the production of foodstuff, milk and butter packaging. It is recommended as an antioxidant in the production of foodstuffs, i.e. it can be added directly into both foodstuffs and its package (paraffinized, waxed, and laminated paper, polymer films and package). The products containing antioxidant СО-3 can be subject to heat treatment.

Stabilizer СО-3 reveals high efficiency when added to polymers used in the production of high-strength thin-walled covers, materials for electric communication cables and pipelines.

Patents

Patents of the Russian Federation, know-how.

Practical realization

- Positive full-testing of the use of СО-3 for a series of polymers

- Production of pilot batches in the Novosibirsk Institute of Organic Chemistry pilot plant

Application

Production of high-strength polymer goods, microelectronics and other products protected from external action and exposure; food industry and pharmaceutics.

Commercial offer

Delivery of pilot batches. Cooperation in production scale increase.

STABILIZER CО-4

Description

Stabilizer СО-4 is a nonstaining and non-toxic thermostabilizer of high performance polymers. It is practically nonvolatile. It is soluble in usual solvents.

Full-scale testing has shown that СО-4 is especially efficient for polymers used in space and aircraft engineering and automobile industry.

In the process of high-temperature processing СО-4 tends to modify the properties of filled polyamides, significantly improving their application properties and specification.

СО-4 can be easily obtained from γ-propanol and available technical raw materials in standard chemical equipment at normal pressure and moderate temperatures. The obtained technical product is purified by recrystallization from organic solvents.

Specification and properties

Pilot batches of СО-4 produced in Novosibirsk Institute of Organic Chemistry pilot plant should comply with the following quality indexes:

BENZON-P STABILIZER

Benzon-P is a non-volatile and non-toxic high efficiency light- and thermostabilizer for organic materials. It is soluble in common solvents.

Benzon-P is applied in production of all-weather goods from polypropylene and polyethylene of both high and low pressure. In concentration of 0,2 % the stabilizer makes it possible to preserve light resistance and thermostability of polyethylene at the levels Irganox 1035, light resistance of polyethylene film d=100 mkm – at the level of Tinuvin 327. On-stream, the goods preserve their natural coloring.

During operation, the product retains its natural color..

Benzon-P can be used in the polymer industry for light-stabilization of organic coatings, in medicine, pharmacy and cosmetology for light-stabilization of organic materials.

BENZON-P is authotised by the Public Health Ministry of the Russian Federation and can be used in the production of polymers which contact with human body and foodstuffs.

Comparison of BENZON-P stabilizer with foreign additives

|

Polymer |

Composition structure |

Concentration mass |

Reference performance |

|

|

Light resistence per hour |

Thermostability per hour |

|||

|

Polypropylene |

BENZON-P Irganox 1035 |

0.2 0.2 |

345 |

80 |

|

Irganox 1010 Tinuvin 327 |

0.1 0.1 |

325 |

85 |

|

|

Polypropylene film |

BENZON-P |

0,2 |

125 |

|

|

Tinuvin 327 |

0,2 |

130 |

|

|

The main technological characteristics of BENZON-P production

Benzon-P can be obtained from gamma-propanol and available compounds by a simple method in standard chemical equipment at normal pressure, with the process tempreture from +145 0С to +10 0С. The obtained technical product is purified by recrystallization from organic solvents.

Technical characteristics

The stabilizer obtained on the technology developed by Novosibirsk Institute of Organic Chemistry should correspond to the following quality criteria: it is a white or slightly off-white powder with melting point 123-125о С; the content of the base substance is not less than 98%.

Patents

Patents of the Russian Federation, know-how

Practical realization

Novosibirsk Institute of Organic Chemistry pilot plant produces development batches of Benzon-P

Commercial application

- Polymeric industry (light-resistance of organic covers)

- Medicine, pharmaceutics and cosmetology (light-resistance of organic materials)

Commercial offer

Pilot batch delivery. Organization of production

N.N.Vorozhtsov Novosibirsk Institute of Organic Chemistry,

Siberian Branch of the Russian Academy of Sciences

9, Acad. Lavrentiev Ave, 630090, Novosibirsk 90, Russia

Tel.: 8(383) 330-73-93 G.I. Schukin, 330-96-61 A.U. Nikulichev

Fax: 8(383) 330-97-52 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.; This email address is being protected from spambots. You need JavaScript enabled to view it.

STABILIZER KALIXAREN

Description

Kalixaren is a mixture of equal quantities of tert-butylated kalixaren (1) and methylene bisphenoles (2):

Kalixaren is used in complex light- and thermostabilization of polyolefines in the production of all-weather film coating providing three-years stability of their properties under unfavorable operating conditions of the middle-zone Russia as well as under the conditions of heat and light exposure. It does not change the natural color of goods, low-toxic, compatible with polymers and soluble in ordinary solvents.

Properties Solid amblychromatic powder with melting temperature 85-110оС, stable to heating up to 250оС.

Advantages

- Polyfunctional: Thermostabilizer of polyolefines two times exceeds the efficiency of antioxidant agidol-2 (compound 2 , R=CH3) – one of the components of kalixaren; high-performance lightstabilizer unlike the feebly marked similar properties of agidol-2.

- Effectiveness: maximal efficiency is attained by using small doses of 0,2-0,3%.

- One of the cheapest nonstaining stabilizers of polymers with complex activity. One- stage production process from available domestic raw materials on autoclave equipment.

- Meets the requirements of polymer goods: thermo- and lightstability, weather

resistance.

Application Complex stabilization of polyethylenes, polypropylenes, rubbers, polystyrenes, polyvinylchlorides, polyamides, polyurethanes, epoxide.

Practical realization There has been developed technological methodology of kalixaren production. Novosibirsk Institute of Organic Chemistry pilot plant has produced development batches of the product available for the further extended testing for the production of all-weather polyethylene; it has been dispatched to the Client and successfully passed the test under the conditions of the middle-zone Russia.

Commercial offer Delivery of pilot batches, extension of application, organization of pilot-industrial production.

Commercial offer

N.N.Vorozhtsov Novosibirsk Institute of Organic Chemistry of Siberian Branch of Russian Academy of Sciences offers:

- Partnership in order to increase the scale of production.

- Organization of Industrial production of products using stabilizers.

- Development of new samples of the polymeric compositions with desired properties.

CONTACT:

N.N.Vorozhtsov Novosibirsk Institute of Organic Chemistry

of Siberian Branch of Russian Academy of Sciences

Promote Applied Research Department

9, Academician Lavrentjev Ave.,

Novosibirsk 630090, Russia

Tel.: +7(383) 330-96-61

Fax: +7 (383) 330-97-52 E-mail:This email address is being protected from spambots. You need JavaScript enabled to view it.

www.nioch.nsc.ru